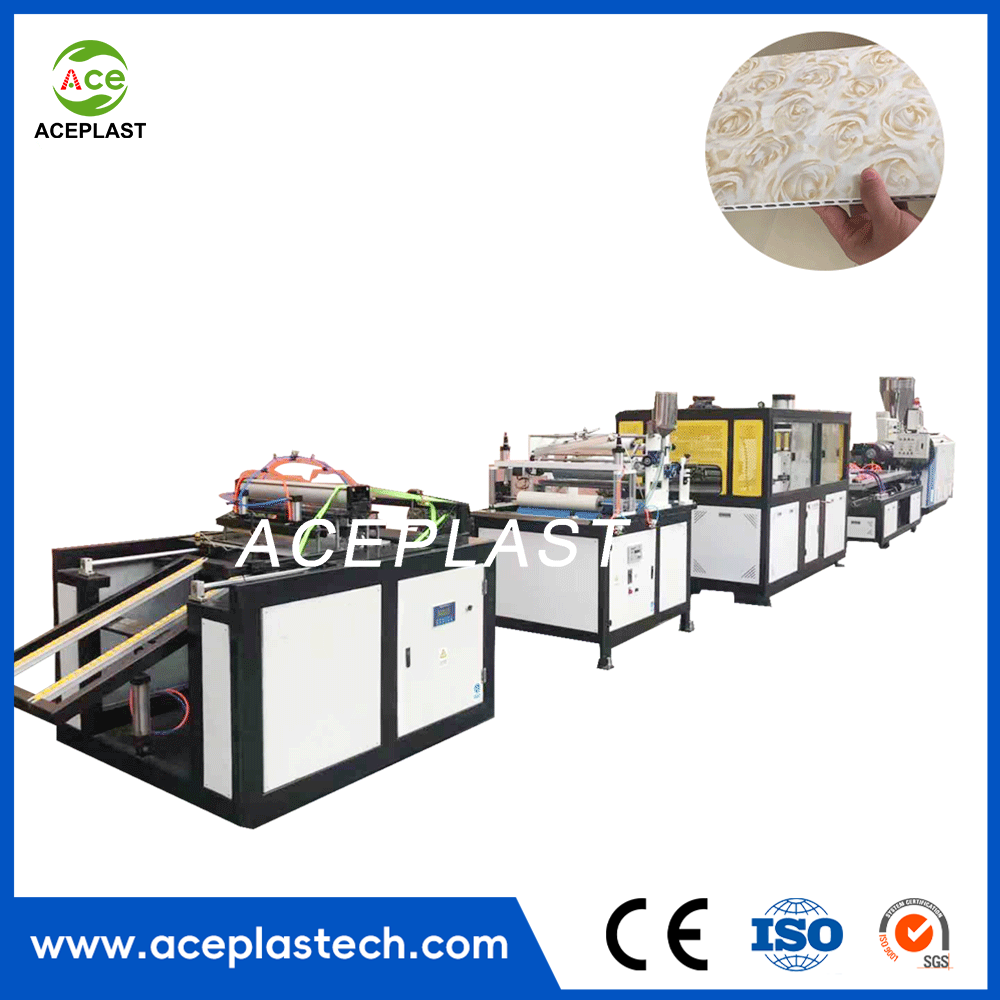

PVC ceiling Panel extrusion line

Product Description:

1) It is mainly used for making PVC/UPVCceilingpanel, wall panel for decoration with different profile break-section moulds.

2) It can also produce Wood+ PVC profiles with different screws in the extruder.

The production line includes auto feeder, plastic extruder, mould, vacuum forming table, haul off unit, auto cutting machine, stacker.

Auxiliary equipments: mixer, crusher, pulverizer, lamination machine, hot stamping machine, printing machine, air compressor and so on.

The working process of PVC panel making machines:

Raw material → mixing → feeder→ double screw extruder → mould → vacuum calibration table → (hot stamping) → haul-off unit → cutting machine → stacker